Steel Fiber For RPC Concrete Reactive Powder Concrete

Specification

Type | Diameter(mm) | Length(mm) | Aspect ratio | Tensile strength(Mpa) |

ZT-0.2/10 | 0.2 | 10 | 50 | 2850 |

ZT-0.5/30 | 0.5 | 30 | 60 | 1100 |

ZT-0.5/35 | 0.5 | 35 | 70 | 1100 |

ZT-0.6/30 | 0.6 | 30 | 50 | 1000 or 800 |

ZT-0.6/35 | 0.6 | 35 | 59 | 1000 or 800 |

ZT-0.75/35 | 0.75 | 35 | 47 | 1100 or 800 |

ZT-0.8/50 | 0.8 | 50 | 63 | 1000 |

ZT-0.8/60 | 0.8 | 60 | 75 | 1000 |

ZT-0.9/50 | 0.9 | 50 | 56 | 1000 |

ZT-0.9/60 | 0.9 | 60 | 67 | 1000 |

ZT-1.0/50 | 1.0 | 50 | 50 | 1000 |

ZT-1.0/60 | 1.0 | 60 | 60 | 1000 |

Types

A) Copper coated steel fiber

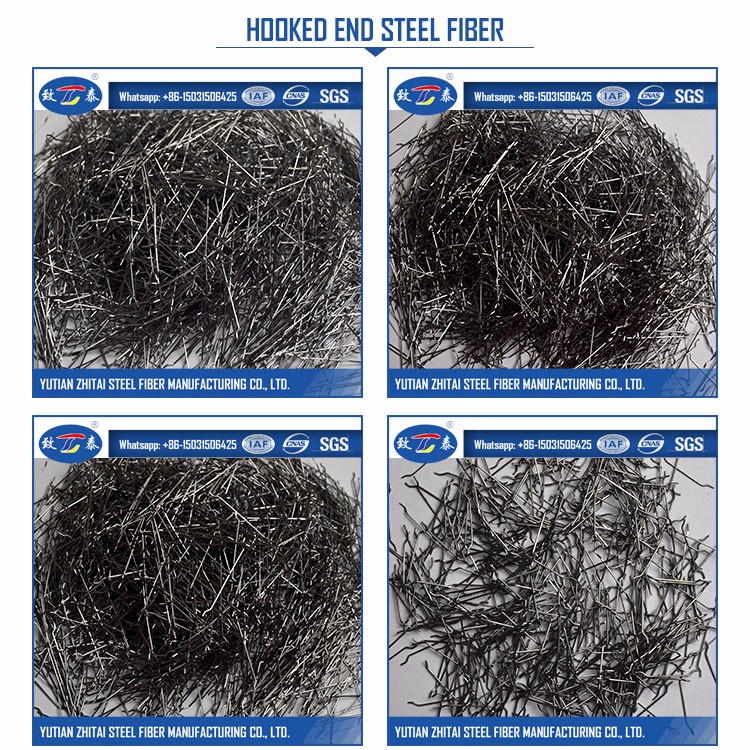

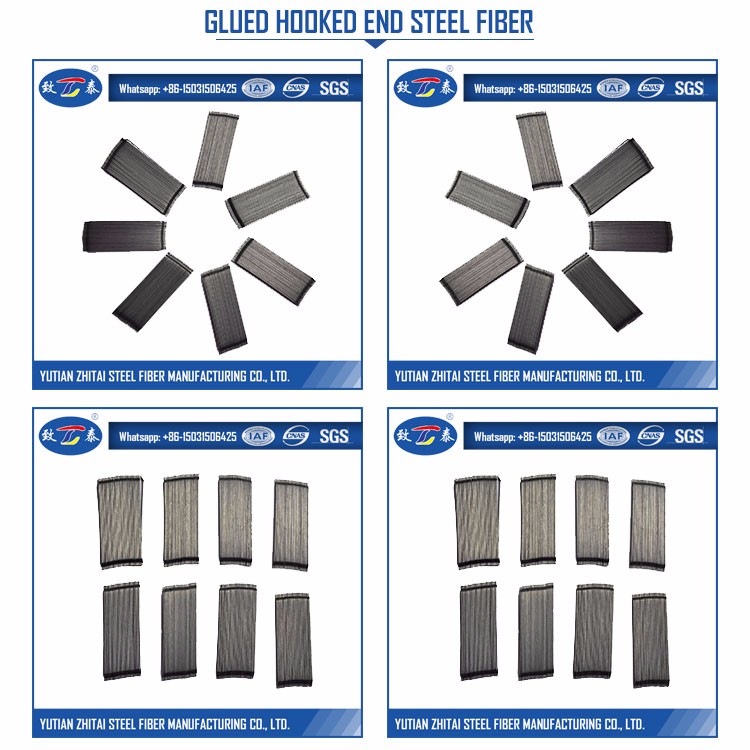

B) Hook end steel fiber (Loose and glued shape)

C) Flat crimped steel fiber

D) Crimped steel fiber

E) Crimped sheet fiber

Applications

A) Industrial and commercial floor

B) Sprayed concrete ( Shotcreting ) in tunnels and mine

C) Precast concrete products

D) Bridges, Culverts and Hydrodynamic structures

E) Seismic resistance structures

F) Highways & Airport pavements

G) Heavy equipment foundation

Advantages

A)Tensile strength is enhanced

B)Adds ductility to concrete

C)Controls cracks

D)Fatigue and impact resistance

E)Reduce material consumption and save cost

F)Less construction time require

G)Longer service time